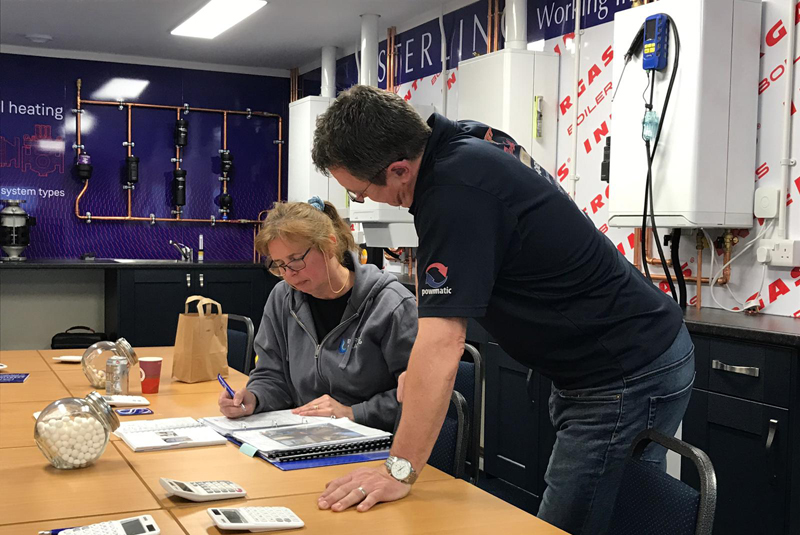

We catch up with Marie Barrett to find out how her summer at Sterling Assessments has been.

How’s the summer been Marie?

I have been doing lots of boiler services and carried out my first boiler install – under supervision of course! I stripped down the old boiler and decommissioned it. I felt quite pleased with myself, as I managed to strip the boiler down and cap off the gas without having to ask my mentor what to do, which helped my confidence. The new boiler was relocated, and I piped it up. We ran the flue, gas and condensate through the loft space and out of a side wall. It was hard work, but I enjoyed it.

Sounds like a job well done! What’s been the most challenging topic you’ve covered with Sterling over recent weeks?

The most challenging topic at the assessment centre recently was flueing/chimney standards. I think this was because we had three assessment papers all on the same day! I did the first paper, then straight after that we had the second paper and I had a bit of a wobble. It had been a really busy, stressful week. The assessors were great though, they made me go and have a cuppa and clear my mind and then I did the third paper with no problem. After lunch I revisited the second paper and passed it no trouble.

The assessments are structured in a specific way and are designed to assess our level of understanding, not just for us to find the answers in the books. This is what makes the written assessments so hard.

Filling in my portfolio is very challenging too. It takes up a lot of time to fill in, print evidence and log. It is hard to fit it in when you also have customers to ring, send estimates, invoices, book in etc. My classmates agree that the portfolio is the thorn in our sides! A lot of it seems to be duplicated.

You spoke about piping the recent boiler installation up? Have you got a favoured method of pipe connections?

I prefer soldering for pipe connections, probably because it’s what I’ve always seen my mentor use. You can make it look really neat and polish it up so it’s nice and shiny, giving you pride in what you’ve installed.

Push fit never seems to be as neat or quite as reliable, from my experiences, at least. I have only had one demonstration of press fit so can’t comment too much. It does look impressive, though there is a bigger initial outlay for the tools that are required. Then again, it cuts down on labour time!