Mike Bennett, Essco Product Manager, explains how the company’s EDGE Heat Interface Unit (HIU) has been designed to maximise the opportunities from Heat Networks.

There are currently around 14,000 heat networks in the UK with 480,000 customers, providing around 2% of current total heat demand. In order to decarbonise buildings and reach Net Zero carbon emissions by 2050 in the UK, heat networks are expected to play an increasingly important role.

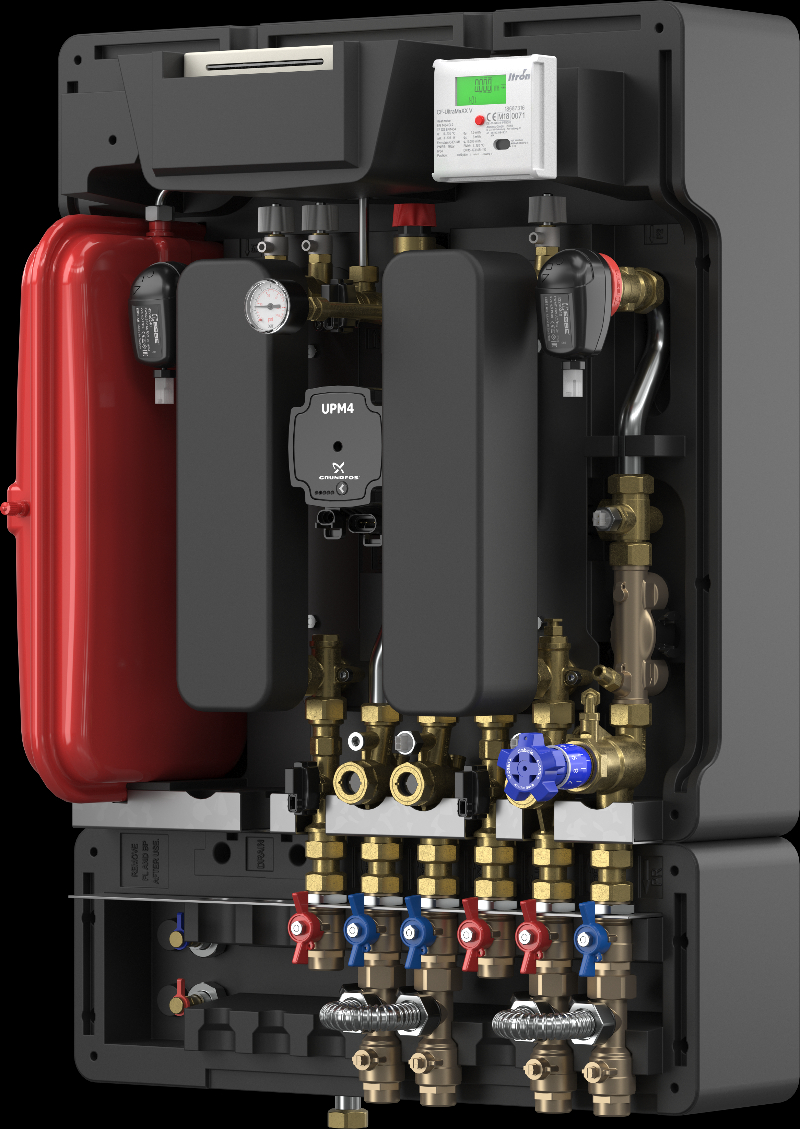

To capitalise on the benefits that heat networks offer, it is vital that systems are designed and delivered with installation, performance, end user control and ongoing maintenance in mind. This includes the heat interface unit (HIU), which is installed in each home to provide independent heating and domestic hot water, similar to a traditional boiler, but powered by centralised plant.

Our team has been involved in the design and supply of many different heat interface units for district and communal heating systems over the past 10 years. With hundreds of combined projects under our belts, it’s inevitable that we have experienced the good, the bad and the ugly.

Some typical issues include:

– Heat losses from the HIU due to inadequate insulation

– Slow delivery of domestic hot water to outlets

– Costly metering and billing technology add-ons

– Problems accessing HIU components for maintenance

– Complicated and time consuming pipework installs

Design priorities

It all starts with the design, and to minimise heat losses we decided that the HIU should be fully Insulated, including the valve enclosure. The total annual heat loss from the secondary systems within the building, including pipework distribution, fittings and any other equipment, is calculated and divided by the number of dwellings. This calculated value shall be equivalent to no more than 100 W/dwelling or 2.4 kWh/dwelling per day on average. Given that this value is considered to be the maximum acceptable heat loss and not a target to reach, Essco recognise that a fully insulated HIU and first fix valve kit should now be minimum requirement if these limits are to be achieved.

The next design priority was delivering a fast response to hot water demands and heating supply, which requires excellent control. Essco uses ESBE PWM 2-port control valves, which are tamperproof, fast acting and go from closed to fully open in just two seconds. The two ESBE flow control valves draw off only the amount of primary flow rate that is necessary to provide residents with the required comfort levels, while maintaining maximum possible efficiency through low return temperatures to the plant room.

Installation and maintenance

During the design process, we aimed to eliminate the need for extra brackets or jigs for installation. Therefore, we created a hydraulically reversible unit that allows for all top, all bottom, or heating bottom entry with remaining connections top entry as standard, meaning one size fits all. In addition to this the EDGE is supplied preconfigured with temperature set points such as heating, DHW and keep warm, so it is very quick to set-up and commission.

To save the installer from squeezing their hands into small spaces or struggling to access parts, all components are fully accessible via the front of the unit, making installation and maintenance straightforward.

The EDGE HIU features inspectable strainers made of site glass for a quick visual check and easy maintenance. These offer two main benefits to service engineers, indication and inspection. The sight glasses provide indication of whether the water is flowing properly, and whether the valve may be blocked with debris and require cleaning. Ordinarily, every year the HIU valves must be isolated, water drained and strainers opened just to see if there is such an issue. Inspectable strainers help to reduce the number of unnecessary inspections by providing year-round visibility.

There are also LEDs on the controller, pump and control valves to show the status of the component for visual fault finding. Whilst off-site, engineers can use our Web App for online access to the HIU controller remotely, with advanced settings for quick commissioning.