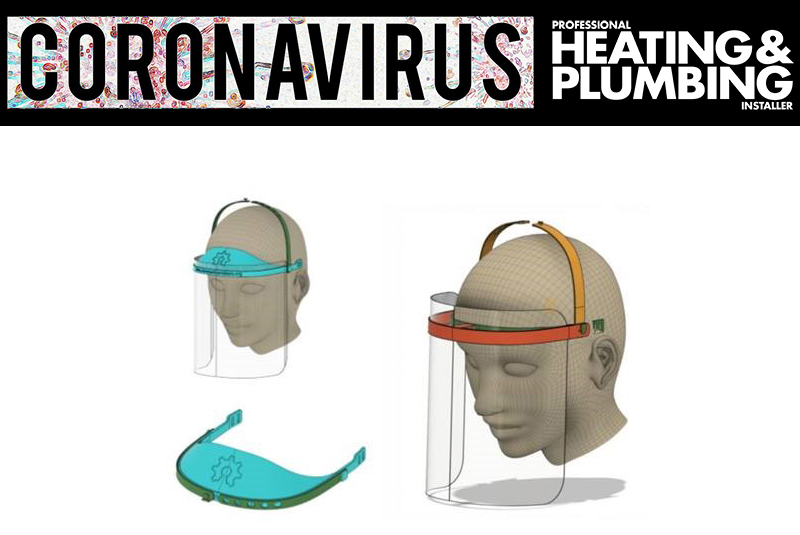

It is well publicised that the NHS is crying out for personal protective equipment (PPE) for its frontline workers who are dealing with victims of the coronavirus pandemic. On hearing this news, design engineers at the Preston-based site of Baxi Heating have taken up the baton, swapping the use of their 3D printers from making prototype boiler components to frames for protective face masks.

Having seen an article about 3D print hobbyist Sid Lovatt, normally working in the retail trade but currently furloughed, who is 3D printing frames for full-face visors for NHS workers, Alan Peel, Product Design Team Leader at Baxi Heating, thought his team could get involved too.

Alan is currently self-isolating, and working from home, but he is still managing his team and is able to programme the 3D printers remotely. He explained how his team are running this important project: “After speaking to Sid Lovatt, I set the 3D printer at 11pm, to print overnight. My concern was that printing one frame at a time would take a very long time and there would be nobody around at night to remove the frames from the printer.

“I needed to try and find a method of printing much larger batches of parts, so the changeover was on a daily basis or even twice weekly if possible. I downloaded some software to my home computer and taught myself how to use it. Using this, I was able to stack up a single batch of 25 components in a single build and set them printing at midnight on 1 April.

“The following night, I pushed the boundaries further by stacking them more tightly and also interlocking them to maximise how many would fit in the 3D printer footprint. It took many attempts and another late night, but I finally managed to increase the capacity in one build from 25 up to 110 components!

“I was able to share the design files with Sid, so he would be able to increase his build capacity also,” added Alan.

As well as 3D printing mask parts for the NHS in UK, Baxi Heating is also able to help colleagues who work for Baxi in Spain, another country that is being hard hit by coronavirus. The design of the Spanish face mask is different to that used in the UK, as Alan explains. “The Spanish version of the Mask support frame was four times higher than the UK version and I couldn’t fit as many in the stack, However, using my new-found programming skills, I managed to maximise the 3D printer footprint build and produce 16 components in a 48-hour period using our second, smaller printer.

“Just a skeleton staff of two or three engineers are working in R&D at any one time now, with the majority of the team working from home, so my colleague in the office, Joseph Folorunsho, Product Design Engineer, is removing the mask parts from the printer and packing them up to be shipped to Sid in Harrogate and our R&D colleagues at Baxi Spain in Barcelona.

“The whole R&D team are pleased that we are able to help provide this much needed, and possibly life-saving, equipment,” added Alan.

David Pinder, CEO of Baxi Heating UK and Ireland, said: “I am really proud of how our colleagues have found ways to pitch in and help with this unprecedented situation. The R&D team have worked on this fantastic project because they were passionate about helping. Colleagues from other parts of the business are using their skills in other ways – for example, our contact centre agents, based in Warwick, have all been set up to work from home, so they can continue to help our customers. And our field service engineers, to whom we have provided appropriate PPE so they can carry out their work safely, are carrying out free of charge boiler repairs for NHS workers.

“This great adversity has brought out the very best in people and I hope that this feeling of national (and international) camaraderie persists long after the current emergency has ended.”