Lee Halstead, Technical Sales Engineer at RWC, provides some examples of how products from JG Speedfit can assist in the installation of kitchens and bathrooms.

The modern kitchen has more appliances as standard than ever before, which means that the pipework is becoming equally complicated and crowded. Newer kitchen trends, such as instant hot water taps and larger fridge freezers with water coolers, only add to the existing mesh of pipework stemming from the dishwasher, washing machine and sink. Equally, minimalist and modern bathroom trends that call for hiding pipework behind walls and increasingly smaller cavities, place specific demands on the plumbing system when it comes to space.

Rooms with limited spaces are becoming more frequent in both retrofit and new-build projects, which makes it increasingly difficult to make connections that require the use of tools, simply due to the lack of room for manoeuvre.

Tool free solutions

If we think about modern kitchens, simply fitting appliances is getting increasingly more complex. The number of appliances seen as standard is higher than ever before, especially in new-builds and retrofit projects. But the amount of space available to fit them all is slowly but surely decreasing, too.

In modern bathrooms, hiding all of the pipework in wall cavities poses the same issue. Indeed, even an experienced contortionist would find it difficult to use tools in these kinds of situations, which is where plastic push-fit fittings can be a real help.

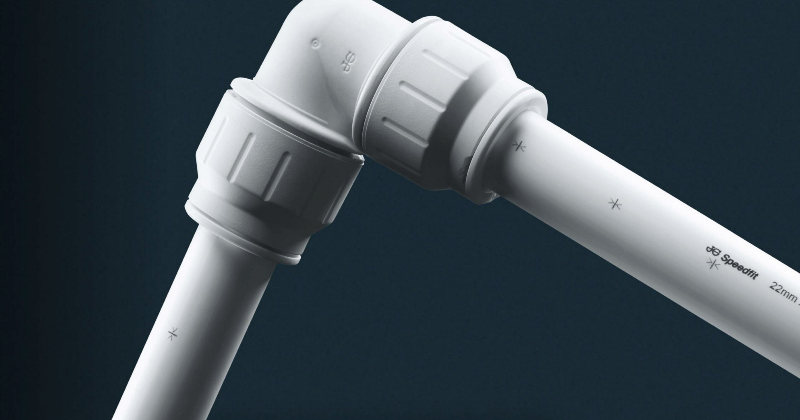

Connections are made by simply pushing the pipe end into the fitting, without the need for any tools. The JG Layflat pipe from JG Speedfit, is available in long length coils and can bend and flex behind the cabinets to enable a fast and easy connection to appliances. From elbows to tees to service valves and flexi hoses and more, JG Speedfit push-fit products help simplify installations under the kitchen sink, behind the cabinets and in wall cavities.

Backflow prevention

Additionally, with a growing number of appliances there is an increased chance of backflow occurring. Appropriate backflow protection valves must be installed on the kitchen’s main water supply to comply with water regulations. This is because a variety of fixtures and equipment, including kitchen sink taps, washing machines, and dishwashers, as well as outdoor hosepipes, can cause backflow. Wastewater from these areas can include everything from cleaning agents to stagnant water from garden pools, all of which may pose a major health risk if they were to enter the mains water supply.

A type of backflow prevention valve, such as a JG Speedfit Double Check Valve, should be installed on the outlets of appliances that provide a higher risk of back-siphonage to offer appropriate protection from backflow. This valve has two internal valves for added safety and only allows water to flow in one direction. Even if one fails, the other can still stop backflow and contamination.

With smaller spaces in mind, having another set of valves to fit presents an additional challenge for installers. So, to enable faster installation of backflow prevention valves, JG Speedfit push-fit double check valves are easy to install, as no tools are required. Additionally, the brand provides a push-fit double check service valve with an integrated water isolation feature. This 2-in-1 valve offers extra advantages by making repair and maintenance work faster and simpler too.

Flexible solutions

While some people do like the industrial look of exposed pipework in their bathroom or even their kitchen, it is more of a niche style than a mainstream one. In most cases, pipes that connect to showers and sinks, need to be hidden behind walls, under floors, or beneath free-standing fixtures.

Soldered copper pipes give the ideal look for exposed pipework, however when this is not the preferred aesthetic, these pipes and fittings can be too rigid to easily conceal behind walls without expending more time and effort than you should. Flexible polybutylene pipes can be easily cabled through joists, behind walls, or fixtures.

Pipes such as the PEX and polybutylene pipes from JG Speedfit, can bend and flex around tight spaces, which make them the natural solution for those type of installations, whilst minimising the need for joints, too.

Twist and lock

To make kitchen and bathroom installation and retrofits more efficient, look out for JG Speedfit’s Twist & Lock fittings range. The fitting’s primary O-Ring seal and Grip & Seal collet with stainless steel teeth mean that each piece in the Twist & Lock range creates a quick push-fit connection that can be swiftly mounted and dismounted, in a flame- and tool-free manner. The push-fit fitting’s primary O-Ring when combined with the JG Speedfit Superseal Pipe Insert, which feature twin O-Rings, also create a multi seal.

The fittings’ non-toxic polybutylene construction makes them durable and watertight, while preventing the need for maintenance. This material is also resistant to corrosion and scale accumulation. Furthermore, the fittings come in a number of bends, including straight, tee, and equal elbow connections, meaning kitchen or bathrooms can be fitted easily from every angle.