David Millward, Group Product Manager at Elta Group discusses key factors to be considered during fan installation to ensure units are achieving optimum performance.

In June 2022 Approved Document F, covering ventilation regulations, was revised as part of the updates to the Future Homes Standard. The changes saw the expected volume of outdoor air received by an occupiable space increase to at least one litre per second per m2 of space, or 10 litres per second per person. With the added risk of cold and flu transmission in colder months, it’s become well recognised that it’s imperative that optimum ventilation performance is achieved to provide good indoor air quality.

The growing awareness was reflected in a survey of 2,000 hybrid working employees undertaken by Onepoll, in which fifty-three percent of those asked showed concern around how poor ventilation and IAQ would impact their health. While a further one in five were concerned about catching diseases such as COVID due to poor IAQ in their workplace.

Replacing stagnant and contaminated air should be done by employing efficiently performing ventilation solutions – to ensure this we need to start at the beginning with the installation process. Within a commercial building, two common fan types used are Axial, which provides straight-through airflow, and Centrifugal, which gets its name from the centrifugal, radial nature of the airflow it delivers. When installing such fans there are multiple key details to consider guaranteeing optimum performance and meet required air levels.

The do’s and don’ts on fan installation

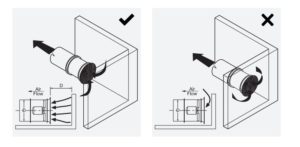

1. Do ensure evenly distributed air is entering the fan inlet

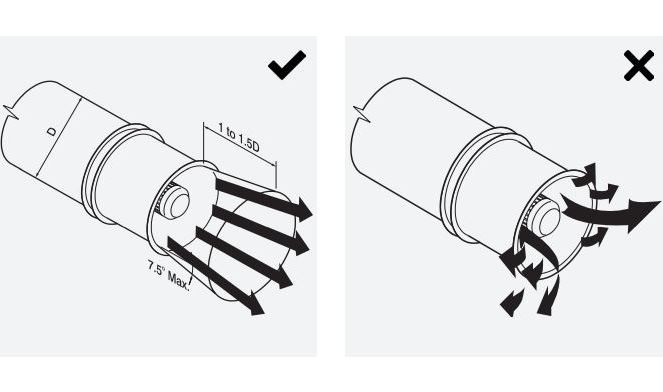

A fan’s performance can be undermined by uneven or excessive airflow entering the unit’s inlet, and this performance loss can be by as much as 45 per cent. While the main flow one side is accelerated, turbulence and high intensity pressure fluctuations occur on the other. These fluctuations can cause resistance which then lessens the ventilation performance of the fan.

When using an axial fan with a free air intake, uniform air intake can be created using inlet cones. Without the use inlet cones, air enters the inlet abruptly which generates turbulence at the impeller. It can also cause the blade tips to be starved of air reducing pressure development capability and causing the fan to stall.

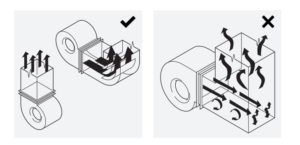

For centrifugal fans, uniform air entering the inlet is equally as important and can be achieved using splitters and turning vanes on the approach to the inlet box to decrease air pressure and prevent air spin. Additionally, such inlet boxes should be adequately sized, as small inlet boxes will generate spinning air which can reduce fan performance by 25 per cent.

Caption: For centrifugal fans, uniform air entering the inlet is important to prevent air spin

2. Do use assistive measures when bends are necessary within vents

Under the updated Approved Document Part F of the Building Regulations it is a recommendation to minimise the number of bends required within ductwork. Understandably though, there are situations in which bends and turns will need to be incorporated. Here, steps can be taken to lower their impact on the functionality of the ventilation system.

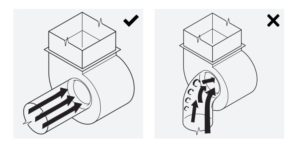

For example, when using axial fans, it’s important to use turning vanes in sharp elbow vanes when adjacent to the fan itself. These assist with the creation of uniform airflow if they aren’t used, and eccentric flow of air will cause part of the impeller to be starved of air and thus the fan will not operate well.

When bends occur in the ductwork near centrifugal fans, it’s important to ensure that the bend ‘rotates’ in the same direction as the impeller. The use of splitters within the bend can help prevent spinning in the airflow.

Caption: For centrifugal fans, it’s important to ensure that the bends near ductwork ‘rotates’ in the same direction as the impeller.

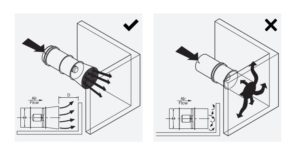

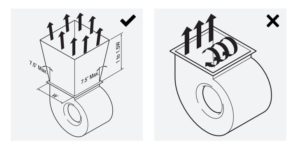

3. Do not block fan inlets or outlets

Caption: Blocking axial fan outlets can increase noise and discharge losses

Caption: Blocking axial fan inlets can lead to the impeller being starved of air

You should allow a gap that is at least equal to one fan diameter between the fan’s intake and any near obstructions. However, it should be noted that even doing this can cause the fan’s performance to be less than rated. When an inlet is obstructed, the impeller can be starved of air, which in turn increases the system’s resistance and reduces airflow being handled by the fan. This applies to all fan types. Additionally, you should always fit an inlet cone on open axial fan inlets.

When placing a fan, you should allow a gap of at least one fan diameter between fan outlet and any obstruction and fit a diffuser on the discharge. When the discharge is too close to a wall the obstruction can generate noise and increase discharge losses.

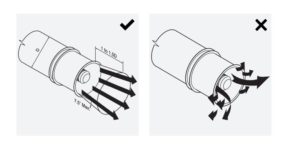

4. Do look for pressure recovery at fan outlets

The fan system’s total pressure can be reduced by using a correctly designed discharge diffuser adjacent to an axial or centrifugal fan’s outlet, when used in a non-ducted outlet system, at a 15 degree or less angle. This arrangement can also reduce discharge losses by up to 75 per cent for both fans, increasing the IAQ level.

Caption: Pressure recovery with centrifugal fans

Caption: Pressure recovery with axial fans

5. Regulation compliance and improving wellbeing

During a period of heightened concern around the need for improved IAQ, it’s imperative that ventilation solutions are installed correctly to ensure effective and optimum performance. Supporting installers, Elta Fans has created a comprehensive ventilation installation guide, called “Give a Fan a Chance”. Delving into the key consideration for Axial and Centrifugal fans as well as Roof fans, it also explores methods for reducing noise and vibration.

To read the full Elta Fans ‘Give a Fan a Chance’ guide click here.