PHPI speaks to Pentair about the opportunities presented by self-regulating heating cables.

Domestic buildings account for approximatively one third of the annual energy use in the UK, which equals a quarter of UK CO2 emissions. Similarly, space heating is responsible for around 60% of domestic energy consumption, with hot water counting for another 15%.

Emerging technologies such as self-regulating heating cables and innovative thermostats present opportunities to install more energy efficient solutions. There are three main requirements for hot water maintenance (HWAT) systems: hygiene and comfort, flexibility and economy. However, finding the right balance between these criteria can be challenging. Reducing water and power use is a key requirement within any energy efficient building. At the same time, the system has to be economical and ideally maintenance-free. To make sure the system runs effectively, pipes must also be protected with high-quality thermal insulation to maintain the desired temperatures. This results in lower heat losses and operational costs.

Conventional solutions, such as recirculation systems, where the pump recirculates throughout the pipe network, can be wasteful if not carefully designed and implemented. Designed to achieve optimal performance with hygiene, comfort and flexibility in mind, the plumbing and heating industry has, over recent years, recognised the need for self-regulating cables.

Self-regulating technology

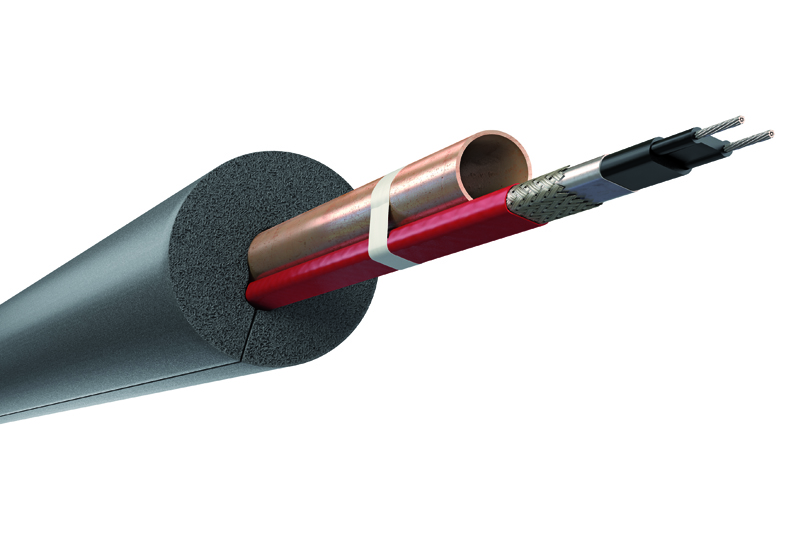

This technology features two parallel conductors embedded in a conductive polymer heating core. Unlike constant wattage series heaters and zone heating cables that produce the same amount of energy all the time, these only emit heat when and where needed. As the temperature rises, electrical resistance increases, and cables reduce power input. They achieve this by reacting to the ambient temperature, reducing output when it is warm and increasing it when it is cold. As a result, self-regulating cables do not overheat. Savings can be made up to 60% compared with recirculating systems.

In addition, self-regulating cables are flexible and easy to install. Space requirements for pipes can be reduced as return pipes are no longer needed, freeing up space for additional equipment. Users can also benefit from low investment costs, as the technology requires only a few components: there are no pumps, control valves or double water meters.

Reducing contamination risk

Innovative HWAT systems respond to increasingly stringent hygiene legislation. With self-regulating cables, the pipe volume is continuously renewed. Because there are fewer pipes, less water volume and lower heat losses, the danger of any bacterial formation is significantly reduced.

Self-regulating cables are fully compliant with the recently updated UK standard for hot water systems, released in September 2015. The BS8558:2015 standard highlights single-pipe systems with electrical self-regulating heat-tracing cables as a suitable and efficient technology for substituting secondary return pipework when hot water recirculation is not practical. The Guide to the design, installation, testing and maintenance of services supplying water for domestic use within buildings and their curtilages (BS 8558) states that: “If it is not practical to use pipework to recirculate hot water back to the heating source – typically, a hot water calorifier/storage tank or tankless/instantaneous water heater – or where the minimum return temperature cannot be guaranteed, a single-pipe system with electrical self-regulating trace-heating cables may be used. Trace-heating could also be seen as a solution if there was likely to be an unreasonable length of time to draw off water before it became useably hot.”

Human safety is also a significant factor for the BS8558:2015 standard. There is increased pressure to prevent bacterial (Legionella) contamination of water. The industry is faced with the continued challenge of installing safe and reliable systems that reduce risk. Self-regulating cables can be an effective solution by maintaining the correct water temperature and preventing bacteria from multiplying.

Smart energy savings

Further energy savings can be realised by combining innovative self-regulating cables with smart control systems. Multi-application centralised control and monitoring systems are preconfigured for commercial and residential heating applications (see Figure 2). They monitor the boiler temperature and ensure that the system is not used exclusively to heat the water, but also the pipe network. In this configuration, power consumption is reduced to a minimum. Whereas traditional control equipment and timers might gain 30% energy savings, users of these systems save up to 50%.

The Raychem ACS-30 heating control system, Pentair’s leading brand in thermal building solutions, features a touch-screen display and provides intuitive application-based control. All heating cable circuits are controlled and monitored from the main interface, providing status updates for up to 20 heating circuits distributed throughout the building at required locations. It limits the heat output of self-regulating cables according to specific requirements of the building. The system combines clock time functions with the monitoring of the boiler temperature to ensure the system is used solely for temperature maintenance, thus avoiding unnecessary heat production and helping to minimise energy consumption.

Building service engineers now have the opportunity to install innovative and smart HWAT systems that increase energy savings whilst minimising costs. These systems combine reliability and compliance with the latest hygiene standards, with more user-friendly functionality to meet the evolving needs of end users.