Thermal imaging cameras can help plumbers and heating engineers spot hidden issues, says Will Jing of HIKMICRO.

Being able to see through walls may seem like a superpower, but with a thermal imagining camera in your toolkit you’ve got that power right at your fingertips. In the past, the high cost of these cameras kept them out of reach for many small businesses, limiting them to specialist surveyors or HVAC engineers. But with technology advancing rapidly, thermal imaging cameras are increasingly more affordable and accessible.

All objects emit infrared radiation (heat), even those that feel cold to the touch. Thermal imaging cameras work by detecting this invisible heat and turning it into a colour-coded image. Warm areas are bright colours like yellows and reds, cooler areas are darker. These cameras can ‘see’ temperature variations, even through walls and floors and can provide precise temperature measurements so it is easy to spot problems like air leaks or insulation issues.

For heating and plumbing engineers, diagnosing an unidentified fault can involve guesswork and trial and error. Getting to the root of a problem might need detailed manual inspections or for walls or systems to be dismantled. Thermal imaging cameras can make life a lot easier, allowing engineers to get a complete picture of what’s happening and where without needing to physically disassemble it.

Under the floor

Once an underfloor heating system is installed, for example, finding faults can be difficult without taking up the floor – a major disruption for the customer and time-consuming for the installer, especially if the location of the problem isn’t clear. A thermal imaging camera allows installers to spot uneven heat distribution or leaks without disturbing the flooring, saving time and minimising disruption.

Track blockages

Thermal cameras are great for tracking down blockages or inefficiencies in radiators and central heating systems – without having to tear anything apart. In hot water systems, thermal imaging can find poorly insulated pipes or energy inefficiencies that might otherwise slip under the radar. Being able to spot these issues right away means installers can fix them quicker, saving time and cutting down on labour costs.

Predictive maintenance

One big perk of thermal imaging is how useful it is for predictive maintenance. For heating and plumbing installers, this means keeping an eye on systems over time and catching potential problems before they turn into expensive breakdowns. By regularly scanning boilers, pumps and pipes, installers can spot temperature shifts that signal something is wrong, like a part starting to fail or a blockage forming in the system.

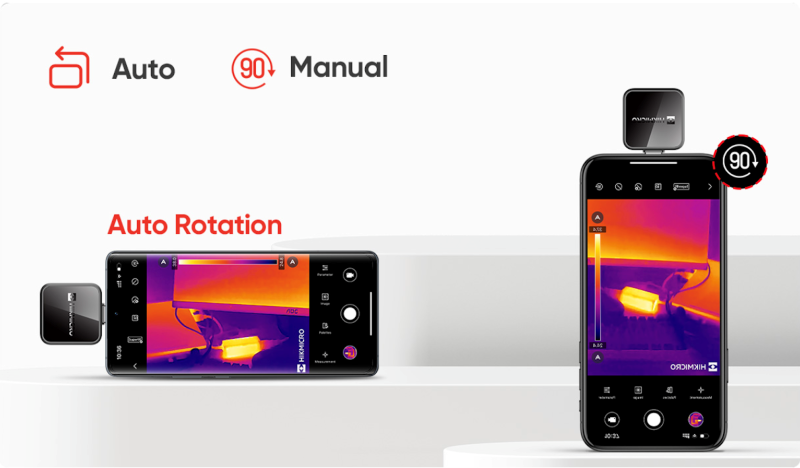

Companies like HIKMICRO have designed thermal imaging cameras that are suited to heating and plumbing installers. Options include the Mini Series, which is designed for use with smartphones and the B Series which captures full-screen radiometric images and automatically pinpoints temperature anomalies. The Mini2 V2, for instance, has a wide-angle, focus-free lens, for scanning large areas such as underfloor heating systems or walls for insulation issues.

The Mini2 Plus V2 includes a manually adjustable focus, allowing for more detailed inspections of specific components, such as distant pipe fittings. All models benefit from HIKMICRO’s SuperIR image enhancement technology, designed to deliver sharper, clearer visuals, improving the accuracy of thermal diagnostics.

By offering a non-invasive way to detect faults, blockages and inefficiencies, thermal imaging cameras save time, reduce disruption and make it easier to catch potential issues before they become major problems.