PHPI talks to Ashley Prescott, Director at Power-Pipe UK, about Waste Water Heat Recovery (WWHR).

How does it work?

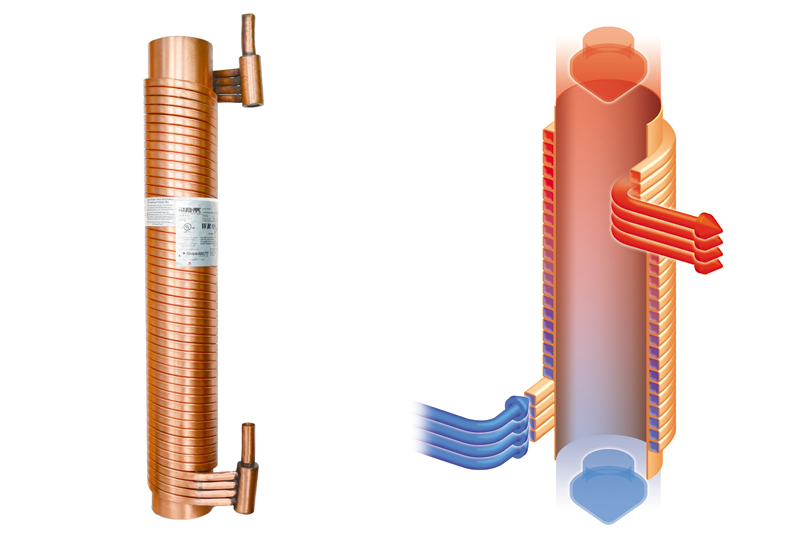

A WWHR system is a simple heat exchanger which recovers heat from outgoing warm waste water –such as shower water – and uses it to pre-heat incoming fresh cold water. It often takes the form of a length of copper piping and installation is straightforward, as it has no specialist design or commissioning and simply replaces a section of a soil stack.

It is most common in residential applications where the heat exchanger is connected to the cold side of the shower’s thermostatic mixer and the water heater. This is why it is sometimes referred to as Shower Heat Recovery. 90% of heat produced during showering is lost down the drain but the majority of it is recoverable through Waste Water Heat Recovery. These systems help to increase the amount of available water in a property whilst reducing the load on its water heating system.

What’s so good about it?

There are numerous benefits but let’s start with the homeowner first. The shower is one of the largest users of energy in the home. WWHR makes showering and other hot water processes more energy efficient. Installing one of these systems can recover up to 70% of this valuable heat energy which would have otherwise gone straight down the drain. Installing WWHR can allow a homeowner to reduce annual energy bills by up to 10% or 500Kwh per person per year. These systems also reduce carbon emissions in a home by between 300 and 1,000kg a year.

The majority of the time occupants won’t even know they are there as they are hidden away behind the scenes in the soil stack and require no user interaction. That’s why, at the beginning of a project, installers need to use this information to upsell.

For developers, a WWHR unit can offer a SAP uplift in the region of 2 to 7%. This is an equivalent energy saving to triple glazing or solar thermal, but at a fraction of the cost, and could be the difference a developer needs to achieve compliance on a particular house type.

Waste Water Heat Recovery really is a no brainer because it is incredibly easy to install and has no moving parts or components. Once it’s fitted, it’s job done. It is expected to last the lifespan of the building if made entirely from copper. If the WWHR comes with 22mm connections, installation will be even easier because there is no need to reduce the size of the incoming mains water feed.

When choosing a WWHR system, it is always advisable to opt for one which has a twin wall between the waste and potable water. This helps to avoid any possible cross contamination between the water supplies and will also allow for a leak to be detected if one occurs.

What about the installation process?

There are three ways to install a Waste Water Heat Recovery system. The most effective set-up is where the pre-warmed water from the WWHR unit is connected to the shower and the water heater. This provides maximum performance and energy savings.

10 steps to installing a WWHR unit

First things first: You will need a black marker pen, two drain connectors, protective glasses, a saw, file and socket head screwdriver. Remember to turn off the mains water supply and flush toilets.

- Make a 40mm mark from the bottom of the waste pipe, which will be the location for the bottom cut.

- Starting from the bottom cut, mark the length of the WWHR along the wastepipe for the top cut.

- Using the saw, make both cuts but ensure the cuts are square to the wastepipe.

- Remove section and file any rough edges.

- Take steel bands off both drain connectors. Slide one on to the bottom cut of the wastepipe and on the other to the top of the WWHR unit.

- Insert the WWHR unit onto the bottom connector and then into the upper cut of the wastepipe. Twist to ensure snug fit.

- Replace steel bands on to the top of the connectors and tighten all connections with the screwdriver.

- Connect cold water supply to the bottom of the WWHR unit.

- Connect the WWHR unit to the water heating system and the cold feed of the shower mixer.

- Turn on the main water valve, run shower and check installation for leaks.

Please refer to the manufacturer’s instructions included with the WWHR when installing a unit as they will vary from model to model.

Design requirements

- WWHR works well for new builds but can’t be easily retrofitted because it is normally difficult to access the pipework of a building.

- The system needs to be fitted on the floor below the shower so can’t be used in a bungalow or ground floor flat.

- WWHR units need to be installed inside the building.

- WWHR is compatible with all water heaters but will not provide any savings if used with electric showers.