Installers on emergency callouts can often be faced with tricky, unpredictable scenarios. Richard Bateman, Product Marketing Manager at RWC UK, discusses why push-fit can help in an emergency situation.

From frozen and burst pipes to poor water pressure, leaking boilers, leaks in underfloor heating and more, there are many scenarios that installers could be facing on a callout. Then there’s the ‘unknown quantity’ of the customer’s plumbing layout and system, making it even more complex.

However, emergency callouts are also an opportunity to make systems better, and to ensure that the fix is reliable and permanent going forward. To do this, installers need to consider the materials they are using, and pipes, valves and fittings are crucial in this respect.

Push-fit solution

Typical causes of leaks and emergencies in plumbing and heating systems include broken or loose seals and corrosion around fittings. This is especially the case in older homes with copper pipework that has been in place for several years, as they are prone to developing pinhole leaks, or if the initial installation was not made correctly for soldered or compression joints.

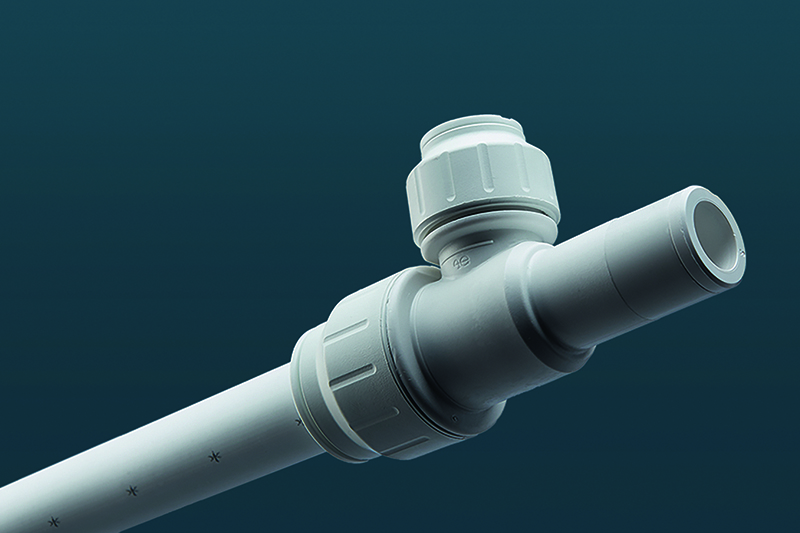

Replacing the joint like-for-like is the common solution, but that can open the possibility of the problem happening again. Another option is push-fit solutions, like those from RWC’s JG Speedfit and SharkBite.

Utilising push-fit technology that has been honed, refined and engineered over many years, push-fit fittings provide a reliable, leak-proof seal, with many coming with long warranties, in some cases up to 50 years.

They are easy to use in emergencies too, as they require no special tools to make the connection. Simply push the pipe fully into the fitting and the connection is made. They are also simple to demount – JG Speedfit products again require no tools to disconnect the pipework, while SharkBite’s can be demounted by hand through easy-to-use disconnecting clips.

Protection from pipe problems

Frozen and burst pipes are another key reason for emergency callouts. When water freezes within pipework, it causes expansion and can split the pipe, leading to flooding and homes being left without access to running water.

For installers on such a callout, once the initial leak or burst has been rectified there are a few best practices to have in mind to ensure this does not happen again – namely these are with placement, protection, and prevention.

Firstly, placement of pipework is a way to safeguard against freezing. Pipes should avoid being routed through areas of the building that are prone to sub-zero temperatures. For instance, avoid putting pipework in lofts or basements.

Next is protection. If pipework must be placed in areas prone to freezing, then make sure they are lagged effectively. Lagging will provide the pipe with insulation, and provide better protection against sub-zero freezing temperatures.

Finally, prevention. Often the best way to avoid frozen pipes is to prevent the water from freezing in the first place. To do that, installers can recommend smart thermostats to homeowners for better programming, and also advise that any pipework that is likely to freeze is drained down.

Installers should also consider replacing copper pipes with plastic pipes. JG Layflat polybutylene pipe is made of five layers, the centre of which is a blue coloured oxygen barrier which prevents the ingress of air into the system, reducing the effect of corrosion on metal components.

Pipework reconfiguration

Going on a callout is much different to working on new build or new projects. Instead of facing the blank canvas of an empty cupboard under the sink, installers could well be met with an array of pipes, valves, and fittings that have been added, chopped, changed and tangled together in an unfathomable knot over many years. Getting to the leak point is one thing, fixing it or fitting new components is another, especially if tools are required.

This can be rectified through push-fit combination fittings that help save space and allow for pipework reconfigurations. For example, RWC’s JG Speedfit has many clever fittings that are simple to use install, such as the double check service valve that combines two features into one, backflow and isolation, and only requires a push to connect.

Another example is JG Speedfit’s Appliance Tee, a second-fix fitting designed for the connection of appliances like washing machines or dishwashers. The valve allows isolation for maintenance or installation, and to install, push the valve fully on to the pipe and thread the appliance hose on to the valve.

Pressure problems

Another common cause of emergency callouts is when a pipe has suddenly burst and has led to flooding. There could be many reasons for this, but a usual one is when there has been a surge of pressure from the water mains entering the home.

Normally, there is a pressure reducing valve (PRV) fitted by the water authorities to regulate the pressure of water coming into the building, and for domestic homes, it is usually between 1 bar and 3 bar. However, if this PRV fails for any reason, a surge in pressure could then cause fittings to blow in the home.

To avoid these circumstances an additional PRV, such as RWC’s 312 Compact PRV from Reliance Valves, is installed to protect homes from any failures in the water authority’s pipework. These valves should be fitted at the point where the mains pipework first enters the property, and usually, these lead into the kitchen.