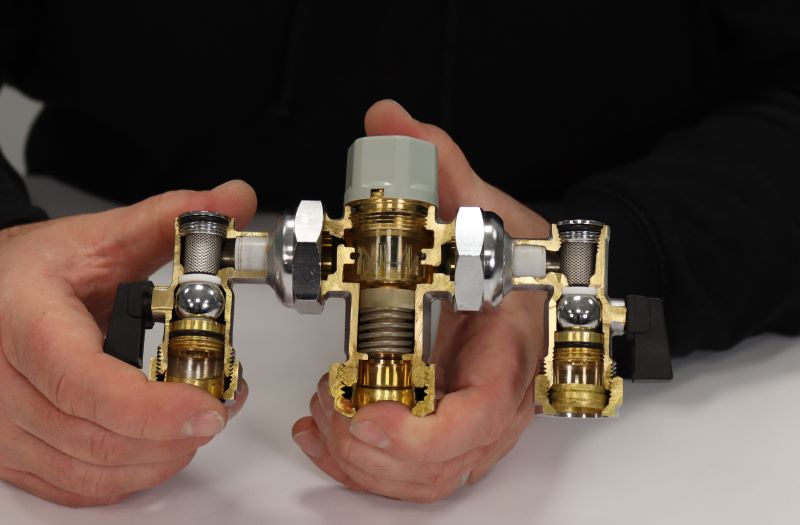

Ed Morris, Technical Manager at Altecnic, delves into the inner workings of a crucial component in plumbing systems – the thermostatic mixing valve (TMV). While it may seem like a small and inconspicuous part, TMVs play a significant role in maintaining safety, comfort, and efficiency in various settings, from domestic systems to healthcare and hospitality settings.

A TMV blends cold water with hot water and maintains this at a set constant outlet temperature to ensure safe and comfortable hand washing, shower and bath water temperatures, reducing the risk of scalding.

The controlling element of the TMV is a temperature sensor which is fully immersed in the mixed water outlet port. This expands or contracts to continually maintain the correct proportion of hot and cold water entering the valve.

Let’s look in more detail how each internal component works to ensure the TMV functions correctly…

Ball Valve Isolation & Strainer

A TMV typically includes ball valve isolators on the hot and cold water inlets. These valves allow for easy maintenance and servicing by enabling the isolation of the TMV from the rest of the plumbing system. When closed, they stop the flow of water into the TMV, ensuring safe access for maintenance or repair work.

Before water enters the TMV, it passes through a strainer. The strainer removes any debris or particles present in the water, preventing them from entering and potentially damaging the internal components of the valve. This helps to ensure the longevity and proper functioning of the TMV. It is important that strainers are cleaned during TMV servicing to prevent potential blockages from a build-up of debris. Information on the frequency of servicing can be found in the manufacturer’s instructions.

Check Valves

Inside the TMV, there are check valves on both the hot and cold water inlets. These valves allow water to flow in only one direction, preventing backflow and maintaining the integrity of the hot and cold water supplies. By ensuring that water flows only from the inlets towards the mixing chamber, check valves help to prevent cross-contamination between hot and cold water lines.

Flow Conveyor

The flow conveyor is a component responsible for mixing the hot and cold water streams to achieve the desired outlet temperature. It consists of a chamber where the hot and cold water streams meet and mix together. The size of the flow conveyor and the ratio of hot to cold water flow determine the outlet temperature of the TMV.

Thermostat

At the heart of the TMV lies the thermostat, a temperature-sensitive element that regulates the flow of hot and cold water to maintain a constant outlet temperature. The thermostat reacts to changes in the outlet temperature by adjusting the position of the valve within the flow conveyor. For example, if the outlet temperature rises above the set point, the thermostat will adjust the valve to allow more cold water into the mix, effectively lowering the temperature. Conversely, if the outlet temperature drops below the set point, the thermostat will increase the flow of hot water to raise the temperature.

Comfortable temperature

By combining these internal components, TMV’s ensure that the water delivered to taps, showers, or other fixtures remain at a safe and comfortable temperature, regardless of fluctuations in the incoming hot and cold water supplies. This not only enhances user comfort but also helps to prevent scalding injuries, making TMVs a crucial component in any plumbing system, especially in environments where vulnerable individuals, such as children or the elderly, are present.

As plumbing standards continue to evolve and safety regulations become increasingly stringent, the importance of TMVs cannot be overstated. Whether in residential homes, healthcare facilities, or commercial buildings, the inclusion of TMVs in plumbing systems exemplifies a commitment to safety, comfort, and efficiency

Altecnic has various models of TMVs that have been specifically designed and manufactured to meet the requirements of domestic and commercial applications. For more information on Altecnic’s TMV range, please click here.