We caught up with Schlüter-Systems to discover more about the company’s range and its commitment to installers.

Q. Schlüter’s portfolio spans a number of product areas. How can this wide selection benefit installers?

Schlüter-Systems has developed more than 10,000 products for the long-lasting installation of tiles and natural stone; they include a comprehensive range of trims, waterproofing, underfloor heating and shower drainage systems. Worldwide, the products and systems have created the very best in bathroom design; in both style and durability. Schlüter’s products and systems are developed and tested to work together; there is one point of contact for the installer and peace of mind is ensured as the combinations are proven.

Q. How important is the installer for Schlüter?

The key to the company’s success has always been the installer; be they independent or employed by merchants or bathroom showrooms. The way the products are installed is crucial to them performing as intended. The Schlüter approach is a holistic one for a room which is challenging when not designed and fitted correctly; the company sells solutions, not just products, to the installer.

Q. What are Schluter’s main USPs?

One of the main USPs is the vast range of products. The biggest benefit is that all products are designed to be used together to create a complete CE-marked system. The level of service is high; from practical training days to ongoing support from the sales and technical teams. The training days consistently receive 100% positive feedback; once an installer sees how easy the products are to install, they become Schlüter advocates. There is ongoing support with area sales managers who build good working relationships with customers and the internal teams have sound technical knowledge. Other resources include datasheets and technical documentation, along with the new website which includes useful videos on the YouTube channel.

Q. What are the key advantages of fitting products such as KERDI-BOARD on a bathroom project?

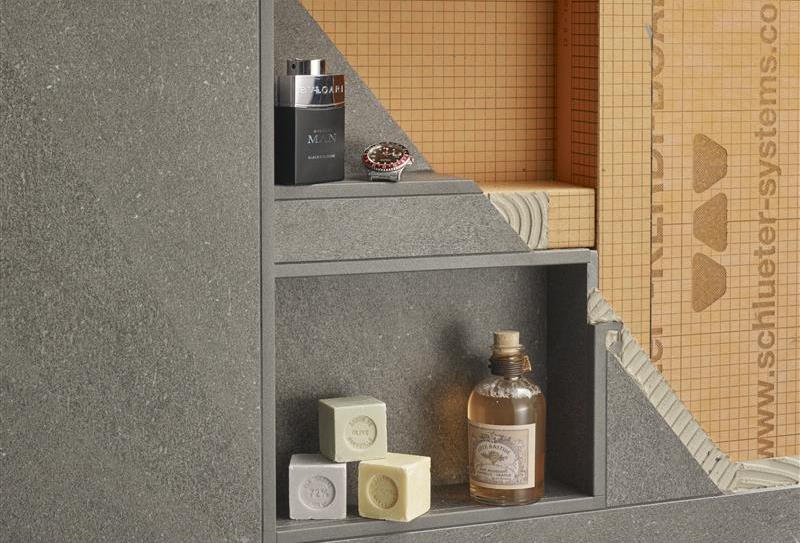

Helpfully, Schluter-KERDI-BOARD, which is BBA-certified and NHBC-compliant, is designed for both retrofit and new-build installations; the different thicknesses of the extruded polystyrene (XPS) panel provide a stable and waterproof substrate for natural stone and ceramic tiling. The panels are available in thicknesses of 5, 9, 12.5, 19, 28, 38 and 50mm and are easily installed across existing masonry, concrete, timber stud frames or lightweight metal framing, with panels featuring parallel grooves also available for creating rounded surfaces, such as for seating or curved walls.

With all thicknesses available in 1.25m or 2.6m lengths, both by 62.5cm wide, KERDI-BOARD is used to create work-surfaces, breakfast bars, islands and vanities. A guide can be downloaded from the website to help choose the right panel for the job. As an example, 12.5mm is the minimum thickness where a stud frame is constructed to 400mm centres. The largest three thicknesses should be considered for construction purposes, while there are also special L-shaped and U-shaped panels for use as pipe boxing, and prefabricated niches in different sizes, with or without lighting, to create storage within walls.

Both sides of the KERDI-BOARD panels have a waterproof, cement-free reinforcement layer; ideal for tile adhesive, either fully embedded or using the dot and dab method. Printed lines help with accurate cutting using a utility knife or power tools.

Q. How is Schlüter committed to improving efficiency and sustainability, both as a company and through its products?

In short, by employing Schlüter’s systems, the installer improves efficiency in terms of installation; it’s all about making the project quicker and simpler. The company is grounded in practical roots as the owner, Werner Schlüter, invented products that helped him to solve problems he encountered on site as a master tiler.

An example of the continuous, efficiency-focused product development programme is the production of the third version of DITRA. The latest version includes EasyCut gridlines that make the mat even easier and faster to cut. The EasyFill design features integrated air release vents for better air circulation which, in turn, make the tile adhesive quicker to spread and help it lock with the modified undercuttings of the mat.

Q. What does Schlüter offer in terms of training?

A range of courses are held at Schlüter’s HQ in Leicestershire; they cover undertile heating, waterproofing, drainage and substrate preparation. Each course is tailored to provide the perfect balance of presentation, demonstration and hands-on time.

Hundreds of installers and contractors are trained every year, with 100% of the attendees in 2023 saying they would recommend the Module One course. Of course, training extends beyond the classroom, and the team also holds trade days across the country, providing product demonstrations and advice.