Diana Puiu, Technical Design & Support Manager from GF Building Flow Solutions (formerly Uponor), outlines what installers need to consider when retrofitting underfloor heating with low carbon technologies.

Building regulations are clear when it comes to replacing wet heating systems. Part L in England and Wales requires a maximum flow temperature of 55°C, while Scotland’s compliance guidance stipulates 50°C. These lower temperature requirements make low carbon technologies like heat pumps and solar thermal systems the logical choice to replace traditional boilers.

Underfloor heating (UFH) systems are a companion for renewable technology due to their large surface area, which results in lower flow temperatures, typically 35-40°C. So, when installers retrofit UFH with low carbon heat sources, they comply with regulations and deliver significant benefits to the property owner, including improved thermal comfort, maximised energy efficiency, and reduced running costs.

Installing UFH is not complicated if you have addressed several essential factors to ensure correct specification. But before you can plan the installation, you must first decide what system is best for your project.

Which system?

Electric UFH systems consist of cables or mats installed under the floor. They can be cheaper and easier to install, but their running costs can be higher, so this type of UFH is better suited to smaller-scale installations such as residential bathrooms or kitchens. If you are installing electric underfloor heating in more than one area, you must ensure that the property’s electrical system can cope with the additional electricity demand, or the UFH could overload it.

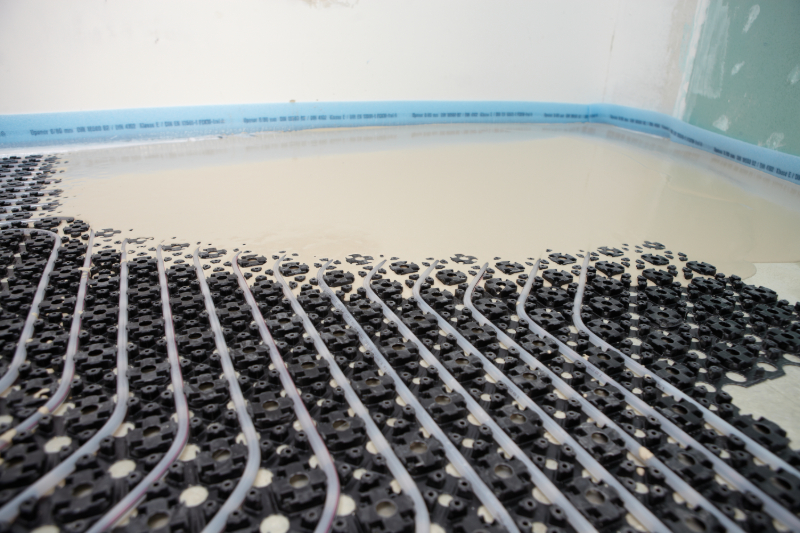

Hydronic (water) UFH systems, which use a network of pipes to circulate hot water through the circuit to provide radiant heat, benefit from greater energy efficiency and reduced heating bills. These systems work well for bigger areas and with low-carbon heating like solar thermal and heat pumps.

Floor structure

The floor’s structure can often determine the choice of system. If raising the floor is not possible, low profile UFH systems, such as the Uponor Minitec, can be installed on top of the existing floor covering or screed or as part of a complete floor replacement.

If the floor structure has a low static weight-bearing capacity, systems like the recently launched Siccus 16 dry UFH system are ideal. Siccus is designed for residential retrofits, requires no screed and has a low profile, minimising disruption and avoiding the need for significant floor build-up. This makes it suited to timber floors or upstairs retrofits with weight and height limitations.

Thermal performance

Good insulation and thermal mass are key to getting the best performance when fitting underfloor heating with renewables like heat pumps and solar. Without adequate insulation, a significant amount of heat can be lost to the subfloor, reducing the advantages of low-temperature heating.

You might need to upgrade the existing insulation in older properties to prevent unnecessary heat loss. The floor’s thermal mass, usually the screed, also plays a big part in how efficient the system is. Getting the insulation right alongside enough thermal mass means better heat retention and a more even heat distribution.

This becomes even more important for commercial buildings, so insulating beneath the UFH pipework will prevent heat from escaping into the floor and direct it upwards instead.

A solid connection

One key area where heat can be lost but often gets missed is where the heat source connects to the UFH system. Using pre-insulated pipe solutions, like Ecoflex Thermo Twin HP, which is designed for heat pumps, can ensure minimal heat loss between the heat source and the heating system. This helps optimise energy efficiency across the whole heating loop.

Flooring material

Another consideration is the type of flooring that will be used above the underfloor heating system. While many floor coverings can work with UFH, installers should pay close attention to thermal conductivity.

In residential properties, carpets and underlay are recommended to have a combined insulating value of no more than 1.5 Tog. Correct insulation is even more critical in commercial environments, where the carpet is specified for sound absorption. As a rule of thumb, values should be no more than 1.5 Tog, especially for heat pump systems.

Materials like vinyl, stone, engineered wood, tile, and polished screed offer excellent thermal conductivity and are ideal for use with underfloor heating systems. However, always check the manufacturer’s recommendations to ensure the flooring is suitable for the system you are installing.

An expanding market

As awareness of the benefits of combining low carbon energy technology with UFH grows, demand will increase further. This is the ideal time for installers to offer low carbon heating solutions and take advantage of this growing market.

However, correct product selection and system design are key. Engaging early with manufacturers like GF Building Flow Solutions will ensure access to technical guidance, design support, and product solutions tailored for retrofit.

To find out more about the Uponor range of underfloor heating systems from GF Building Flow Solutions, including its latest addition to the range – the Siccus 16 please click here.