LowBoard was launched into the market in 2012, and a little over ten years on the company has now introduced a new, low profile, overlay panel, LowBoard 2.

The solution consists of routed lower and upper panels with a combined profile of just 18mm – the company believes it is the thinnest overlay system on the market. Its predecessor, LowBoard, had a lower panel profile of 15mm but, like other overlays, LowBoard also required a ply upper layer which can add around 6mm to its overall depth.

Omnie says that LowBoard 2 has a 15% higher heat output than its predecessor: its lower and ‘over’ panels have pipe channels that tightly sandwich and encapsulate the warm water pipe. The routing follows Omnie’s patented multi-directional pipe channel pattern, eliminating the need for separate straight and loop panels while also allowing the warm water pipe to be easily laid around any planned room layouts. The channels are spaced 150mm apart for optimal heat output and transfer.

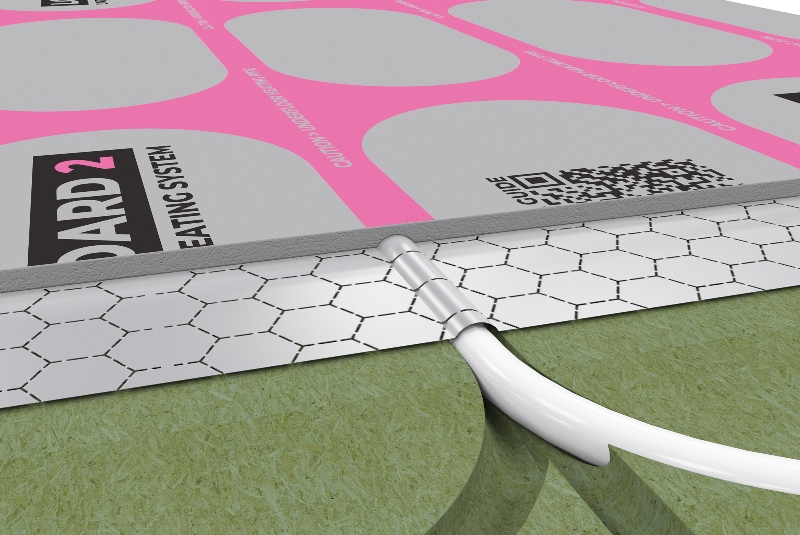

The upper ‘over’ panel is 6mm thick wood fibre (or 12mm plywood for tiled applications) and the proportional pipe channel pattern places the encapsulated warm water pipe within 3mm of the floor surface.

Bonded to the over panel is a layer of patented aluminium AL HEX foil diffuser with its distinctive hexagonal perforated design. This diffuser technology improves the in-channel, foiled surface area that is in contact with the warm water pipe. The result, according to the company, is greater heat output, better heat transfer and a more even heat distribution that avoids the risk of damage due to heat ‘striping’.

Retrofit-ready

“We’re very excited by how LowBoard 2 could help transform home heating and the requirement for low-carbon energy systems in the future,” said Brendan Hourican, Managing Director at OMNIE. “It’s important that heat pump performance is optimised if we’re to see its widespread uptake across the UK. This will help ensure that running costs are kept low and that homes are comfortably warm in winter. LowBoard 2 is low-temperature, retrofit ready and designed with heat pumps in mind. It can reduce heating bills by up to 20% compared to aluminium spreader plate systems which also use heat pump as the heat source.”

Pipe pattern

On the top surface of the upper panel is a printed warning exactly matching the pipe pattern to ensure that other trades do not inadvertently pierce the pipes, either when room fixtures and fittings are being installed (such as kitchen cupboards or bathroom fixtures) or at a future date. At the panel’s edge, the channels are fluted to allow for any small deviations between panels when they are laid that may otherwise result in the pipe being inadvertently pinched.

Installers are also provided with a detailed design plan for the pipework, created by the Omnie team, showing both where the pipes should be laid and which pipe coil length to use for each circuit. This is to help to eliminate the time usually spent measuring up the floor before ordering the pipes, and it avoids any risk of having to join lengths of pipework under the floor covering.

Once laid during first fix, the company says LowBoard 2 can safely be walked on by other trades before being covered by the final floor finish.

To watch a video about LowBoard 2 please click here.