Mark Hall, Head of Mechanical Engineering and Devices at Fernox, explains why it is essential to protect heat pump systems from the adverse effects of circulating debris and discusses the role of system filters as part of a comprehensive approach in line with Part L of the Building Regulations.

The industry is currently experiencing a significant shift from gas boilers to the adoption of heat pumps, with projections that the UK will reach 1.9 million installations a year by 2035. With rapid and continued growth of this market, installers are quickly educating themselves on this emerging technology as new build properties and existing households move away from traditional gas boilers to more sustainable, efficient heating and cooling solutions.

However, heat pumps are vulnerable to biocidal contamination due to the lower flow temperatures, and similar to traditional systems, are affected by the losses in performance caused by sludge, scale, corrosion and other installation debris. Therefore, to ensure their energy performance is optimised and the heat pump performs as expected, the system must be properly protected and maintained.

Much like a traditional heating system, a heat pump system comprises water-filled pipes, along with radiators or underfloor heating. Without the proper protection, it can be susceptible to issues such as corrosion, scale build-up, and microbiological fouling.

Water treatment

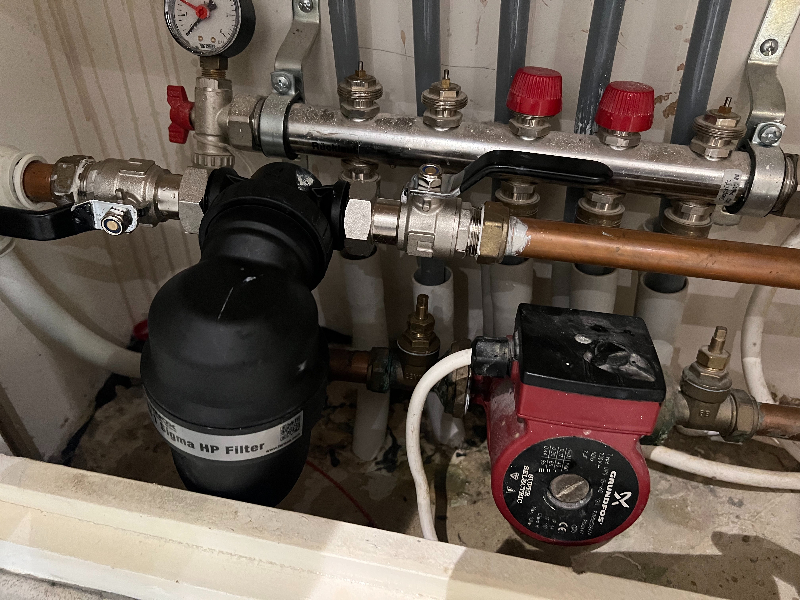

In accordance with the latest version of Part L of the Building Regulations and BS 7593:2019, heat pump systems must be treated with effective chemical water treatment to prevent scale, corrosion, and biofilm formation. An in-line filter should also be fitted to capture and contain debris already present including installation debris, that may have entered the system.

Choosing the right filter

When selecting an in-line filter, it is important to choose one that has been specifically designed for heat pump systems. Until recently, most filters on the market were designed for traditional gas boiler systems, but there are some fundamental differences in the flow rates of heat pump systems that present specific challenges for magnetic filtration.

Not all filters used on heat pump systems are alike, so it’s important to understand the key features and considerations that will help you consider the best specification and choice of filter for your customer. Look for filters that have the following characteristics:

Effective at capturing and containing debris, even at high flow rates

One significant distinction between heat pump and traditional gas boiler heating systems is the flow rate. Heat pump systems typically operate across a flow rate range of 6-40 litres per minute, as opposed to the 12-15 litres per minute range of a typical gas boiler system. To be effective in any system, a filter must be capable of capturing and, importantly, containing various types of debris, including magnetite, haematite, and scale.

In higher-flow heat pump systems, traditional magnetic filters might not effectively retain captured debris, due to ‘wash off’, potentially causing damage to system components and reducing efficiency. Filters designed with particle separation baffles for efficient debris capture are better suited to high-flow rates – for instance, the Fernox TF1 Sigma HP Filter which has been purpose-built for heat pump applications and boasts a10-year warranty.

Minimises pressure loss

Another consideration is selecting a filter that does not impede the pressure of the water. Heat pump systems rely on specific Co-efficient of Performance (COP) levels for efficiency. Therefore, selecting a filter with market-leading Kv values for minimal pressure loss is crucial in maintaining heat pump efficiency. Furthermore, filters with full bore isolation valves enable water to flow without additional restriction.

Prevents microbiological fouling

A traditional gas boiler system typically operates at between 60°C and 70°C which naturally disinfects the water and reduces the opportunity for microorganisms such as bacteria and fungi to thrive. In contrast, the optimum operating temperature for a heat pump is between 35°C and 45°C, making it an ideal environment for bacteria to feed and multiply which in turn, leads to reductions in system performance with the formation of biofilms and slimes blocking heat exchangers, diverter valves and pipework. This type of contaminant is extremely difficult to flush, causing accelerated degradation of the system – and potential costly system repair.

Until recently it has not been possible to trap these bacterial slimes using traditional magnetic filters, but with the development of dedicated heat pump filters this is now possible. For example, the TF1 Sigma HP Filter uses patent pending flow disruptor technology to capture this type of debris at fast rate flow rates. Whilst filtration is important, it is complementary to the role of chemical water treatment, which is crucial to prevent the development of microbiological fouling in the first instance. Effective biocides and inhibitors such as the Fernox Biocide F7 and Protector F1 are best-in-class formulations that prevent this happening.

Performs as expected

When choosing heating system components, prioritise high-quality filters that are easy to install and maintain, ensure leak-free operation, and ones that have undergone comprehensive testing. For instance, the TF1 Sigma HP Filter has been submitted to rigorous testing, including repeated pressure cycling up to 10 bar and temperature cycling up to 90°C during its design, development, and production phases.

Main Image: Fernox