Richard Bateman, Product Marketing Manager at RWC UK, explains why thermostatic mixing valves (TMVs) are crucial to keeping people and water supplies safe, how they should be installed, and what to do to maintain them.

A fundamental part of any hot water systems is the TMV. Designed to blend hot and cold water to a pre-set temperature, these are crucial safety valves which prevent the risk of scalding, while allowing hot water systems to run at high enough temperatures to prevent Legionella bacteria from breeding.

TMVs are regulated by law. It became a legal requirement to install TMVs in all commercial and domestic new builds in 2010, as well as properties undergoing a ‘change of use’ after 2012. These valves are also regulated by the Thermostatic Mixing Valve Manufacturers’ Recommended Code of Practice for Safe Water Temperatures, the NHS Estates Guidance Note for Safe Hot Water and the Health and Safety Executive (HSE).

Getting the right TMV

Given the importance of fighting off harmful Legionella bacteria while also delivering water at safe temperatures, it is vital that the right TMV is used for the job, and each application must be considered carefully.

As outlined in Part G of the Building Regulations and the TMV2 Scheme, TMV2 certified valves should be used in domestic, commercial and public buildings. Under this scheme, TMVs must maintain a safe and stable temperature of under 48°C at all times and quickly shut off in the event of hot or cold-water failure.

In commercial applications, TMV2 certified valves must also be tested annually to maintain the certification. In these settings, a single TMV can be used to serve multiple outlets, ideal for a group of basins in public toilets or showers in a gym.

On the other hand, in healthcare settings, a risk assessment should be carried out and TMV3 certified valves must be specified accordingly. Crucially, a valve must be installed to every water outlet identified in the risk assessment.

The Health Services Information Sheet No 6, published by the Health and Safety Executive (HSE), provides useful insight into risk factors and “at risk” groups. These valves must comply with the Care Standards Act 2000, which states that any healthcare building housing vulnerable people must have TMVs compliant with the NHS Model Engineering Specification D08.

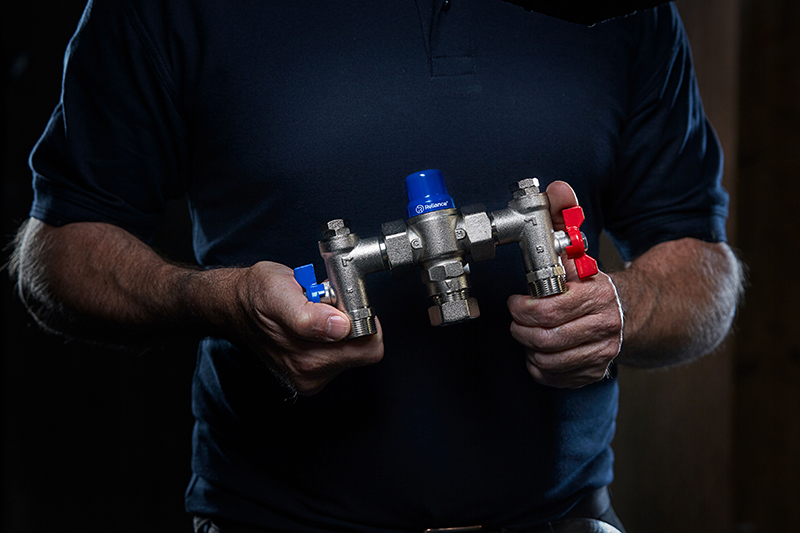

With a variety of TMVs to choose from, the key is understanding the application first. At RWC we offer a choice of TMVs from our Reliance Valves brand including Heatguard Dual and Ausimix, suitable for different types of application with the relevant TMV2 or TMV3 approvals.

Check the flow rates

It is essential that when selecting a TMV it performs at the flow rate required for that specific application. For instance, although TMV2 allows for ‘group mixing’ to multiple outlets, the valve must be sized accordingly to meet the demand. If undersized, this may result in insufficient hot water reaching the required outlets.

Installers should refer to TMV product data sheets, which contain information and graphs on flow rates. If in doubt, consult the manufacturer. RWC’s technical team, for example, is happy to help with understanding the application, legislation and flow rate requirements.

Preparing for installation

Before fitting a TMV, there should be due care and attention to preparing and installing the pipework first. For a group mix valve, ensuring that the TMV is as close to the first outlet as possible can prevent the risk of a stagnation point, which can lead to Legionella bacteria breeding in the system. For TMV3 installations, regulations stipulate that the valve must be within two metres of the tap.

For commercial and healthcare applications, as the valve must be regularly maintained, we would always advise that the TMV is located in an easily accessible location. For instance, this could be in a maintenance hatch, or surface mounted, rather than being hidden out of reach inside cavity walls. For tighter spaces, try Reliance Valves’ Compact Ausimix Telescopic TMV. With adjustable union connectors, its application is flexible, especially in retrofit installations. It is also WRAS approved and certified to both TMV2 and TMV3.

Effective installation

Thermostatic mixing valves will fail to regulate the temperature of the water effectively if they are incorrectly installed. This leads to ongoing maintenance and servicing to diagnose the issue and, in healthcare applications, the outlet will be put out of use, which can cause major disruption.

To prevent this, it is important that the hot and cold feeds are plumbed in the right way around and that the correct adaptors are put on the correct ports. Make sure that there are service valves either on the valve itself, or that they are plumbed in on the pipework leading up to the TMV. These simple but critical steps are vital to ensuring that the TMV operates efficiently and that the water supply can be isolated for testing and maintenance purposes.

Testing, maintenance and servicing

After the valve has been installed, it needs to be tested, maintained and serviced at set intervals, as stipulated by the relevant scheme. Each application has its own temperature setting requirement – for example, in both schemes, an assisted bath must be set to 46°C (allowing for a 2°C fluctuation), whereas an unassisted bath would need to be set at 44°C.

TMV2 valves should be checked by measuring the mixed water temperature, then isolating the cold water supply to the TMV. Once the supply is isolated the valve will begin to shut-off. This can happen instantly, however the requirement is that the outlet must not allow more than 120ml in a minute to satisfy the test requirement. Repeat this step for the hot water supply. If the water’s temperature has changed by 2°C or more, or if the failsafe doesn’t work, a full service and recommission will be required.

For TMV3 valves, the original installer is required to check the valve still operates 6-8 weeks after installation, with test frequency set at six-month intervals thereafter. If the valve fails within the initial period, the installer must rectify the issue and re-test the valve, then return again in six weeks’ time.

Keep a checklist of every TMV that you are installing, the temperature that it has been set to and record that the failsafe function has been tested and is working correctly. Copies of these records can be left with the building owner/landlord, helping to ensure that future testing and maintenance is done under the same temperature parameters.

The right way

Scalding is a major hazard. While thermostatic mixing valves are designed to prevent this from happening, they can only do so if they are fitted and maintained correctly. Whether it is domestic, commercial or in a healthcare setting, using and installing TMVs in the right way is vital to ensuring a safe and uninterrupted supply of water.