Ed Morris, Technical Manager at Altecnic, provides a quick guide to Pressure Reducing Valves.

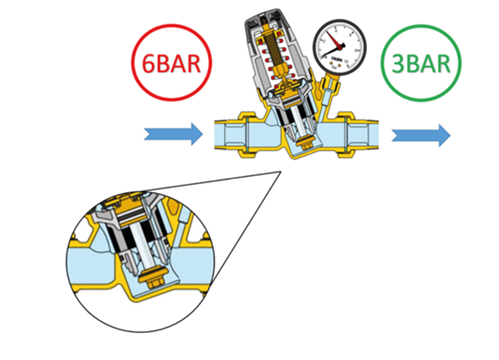

A Pressure Reducing Valve (PRV) is a frequently misunderstood product. The operating principle is simple enough; they reduce the incoming pressure from a mains supply or a boosted supply within a building. Their purpose is equally obvious – limiting high-pressure water that can seriously damage components in a heating and potable water system, which can lead to damage or even burst pipes and seals.

It is important for an installer to understand how a PRV works, and how they can optimise them for the end-user. Here, we explore some key considerations when selecting and installing a PRV:

Why fit a PRV?

PRVs are installed in residential, semi-commercial and public buildings to reduce and stabilise the inlet water pressure.

If the differential pressure is too high it may prevent control valves from operating or isolating and on potable water application, the force of water from the tap or other outlet may be too fierce which could cause localised flooding.

PRVs are designed to reduce water pressure and maintain it to a set level preventing damage to those components installed downstream of the PRV.

Where can I use the PRVs?

PRVs are generally used on water and potable water applications. Some PRVs are also used on compressed air, natural gases and natural non-adhesive fluids. However, they should not be used on salt water, petrol or diesel.

What is static pressure?

Static pressure is the head or pressure of water in a system when that water is at rest. Static pressure control is therefore the maintenance of a set pressure within a system when there is no demand, i.e. no flow. This is particularly useful for single point of use outlets, especially where protection is required due to low pressure rating of, for example, washing machines and showers.

What is dynamic pressure?

Dynamic pressure, in comparison, is the static pressure of the body of water but it also includes the momentum of the fluid in motion. Therefore, dynamic pressure control is the maintenance of a set pressure within a system when the water is moving.

The key difference is that a dynamic PRV will only control the pressure when water is moving. If there is no demand the pressure can creep up without regulation. Setting is done using a pressure gauge installed in the pipework or in the valve. Ideally the pressure gauge should be upstream of the valve.

Which PRV should I use?

There is a selection to choose from based on the application (cold water or hot and cold-water service), with or without a pressure gauge, set using a screwdriver or a Dial up setting.

There are also many considerations that an installer must take into account when selecting a PRV, such as:

- Connection size and type

- Set pressure

- Temperature

- Back pressure

- Required capacity

What is ‘drop-tight’ control?

When a PRV operates under both flow and no-flow conditions, this is known as ‘Drop-Tight’ control. ‘Drop-Tight’ control prevents the pressure from “creeping” (an increase in downstream pressure under no-flow conditions).

Can the end user adjust the pressure themselves?

Yes, as the valve works off a spring and diaphragm you can set the outlet pressure by turning the screw on the top of the plastic cover (Caleffi 533 Series) or the by turning the pre-adjustable dial up knob complete with pressure setting indicator (Caleffi 535 series).

Can the PRV be installed in any orientation?

The PRV has a flow direction arrow cast onto the body – the valve must be installed with the flow in the direction of the arrow. The valve can be installed horizontally or vertically but must not be installed upside down. If the valve is installed horizontally than the cartridge should be vertically mounted.

Where should a PRV be installed?

The PRV should be installed downstream of the main isolating valve on the cold-water inlet. In apartments these may also be installed after the main inlet valve of the recirculating hot water system.

As you may need to access the cartridge for future service or replacement, care should be taken in respect of where the valve is installed so that you have sufficient room to maintain the valve

Do I need a strainer in the system to protect the PRV?

A strainer will protect a PRV from debris that may flow in the pipeline, which could disturb the operation of the valve. The strainer may already be installed as part of the system design. For example, Altecnic 533 and 535 series PRVs both incorporate a strainer screen as part of the cartridge assembly.

www.altecnic.co.uk/domestic/plumbing-heating/pressure-reducing-valves

Altecnic’s PRVs

Altecnic offers a range of PRVs for both commercial and domestic applications. For example, the Altecnic 533H series PRV was designed for small applications such as apartments to protect water systems where valve size and lack of noise are important aspects. This specific series of pressure reducing valves is certified according to the EN 1567 standard for operating with inlet water temperatures of up to 80°C.

Alternatively, Altecnic also offers PRVs for commercial applications. For example, the 300 range of commercial or industrial PRVs includes an automatic pilot-controlled valve and can regulate to a near zero flow as standard with no need for special low flow devices or bypasses. WRAS approved with a robust design the Prescal 300 is a durable, accurate PRV for larger projects.