Combating the problem of air within a heating system is key to ensuring maximum efficiency, says Kevan Peaker, UK Business Director at Spirotech. However, there still remains a common misconception that an automatic air vent alone can successfully do the job. Here, he explains how high system performance can only be maintained by employing the method of deaeration.

Despite a growing awareness of the importance of air removal in ensuring full system health, there still remains a common misunderstanding that installing an automatic air vent (AAV) will remove all air from a system, thus reducing the problem of corrosion. However, whilst an AAV is successful in eliminating what is known as ‘free air’ during the initial filling process, it is incapable of removing free air during system operation.

Microbubbles or ‘liberated gases’ are the result of gas being released from the system liquid after applying heat. Over time they can cause significant damage to the system and often they go completely untreated.

So what exactly is the difference between AAVs and deaerators?

So what exactly is the difference between AAVs and deaerators?

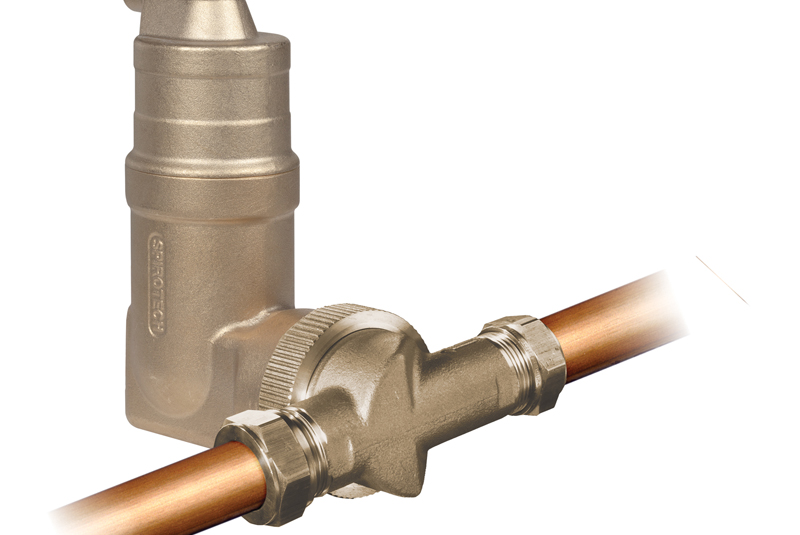

Deaeration, also known as ‘air separation’, is the process by which a significant amount of air is removed from a heating system. It plays an essential role in maintaining system efficiency, as air is the cause of a build-up of debris that considerably reduces system performance. Going above and beyond the role of an AAV, a deaerator, such as the SprioVent RV2, removes microbubbles from the system liquid.

Due to their microscopic size, microbubbles have a very hard surface tension, which means they cannot coalesce. Therefore, ‘coalescent deaeration’ – the process carried out by AAVs – is incapable of removing the root cause of air in heating systems.

A deaerator should be installed at the hottest point of a system, on the common flow. The key element of the SpiroVent RV2 is its internal cluster of Spirotubes; a spiral made up of tube arrangements that provide a controlled decrease in velocity within the turbulent zone. This leads to a laminar “no flow zone” thus creating an environment that encourages microbubbles to rise out of solution and ultimately be released by the deaerator.

This is in stark contrast to an AAV, which is fitted at the highest point of the system to release free air only, without ever removing the liberated microbubbles. An automatic air vent is useful for removing large quantities of free air during the initial filling of a system, or for the inlet of air during the draining of a system. However, due to its inability to catch and release tiny microbubbles, an AAV is not a sustainable solution for the continuous and thorough removal of air from a heating system.

A combined approach

Although air is the root cause of a contaminated system, and by installing a deaerator alongside an AAV, system performance will be much improved, it is only one part of successful water treatment.

To ensure full system health over a long period of time, a combined approach is key. This includes two other essential practices: dirt separation and chemical application.

Dirt separation

The magnetite debris (or dirt) has a significant negative impact on overall system performance. To combat this, a dirt separator should be fitted in order to successfully collect and dispose of any debris within the fluid.

The dirt separator, used in conjunction with a deaerator, should have the ability to remove both magnetic and non-magnetic dirt, ensuring that a system will be cleared of debris. They are to be installed on the return, removing the dirt from the circuit before it enters the boiler. Dirt separators do so by holding the dirt particles in a chamber, which can be then emptied independently.

Chemical application

Having been long considered the go-to solution for managing system health, chemicals can be effective in maintaining maximum boiler efficiency, if applied and dosed correctly. In doing so, a protective layer on the surface of pipework and radiators is formed, in turn protecting them against corrosion within the system.

However, this protective layer is susceptible to damage from oxygen that enters the system through a process called diffusion. To avoid this, it is important to check the levels of inhibitor – created by the chemicals – to ensure they are sufficient.

Maintaining system efficiency starts with air removal

Maintaining the highest rate of system efficiency over an extended period of time requires a fully comprehensive combined preventative and reactive approach to problems that arise over time. Whilst dirt separation and chemical application are well-known water treatment solutions, the importance of air removal is still relatively unknown within the UK market, but remains a crucial measure in ensuring maximum system efficiency.

The installation of a deaerator is essential to this air removal process; an AAV alone will not solve a system’s air problem. Air is the cause of a system’s pain; so make sure that it is treated correctly.

For more information on Spirotech, visit: www.spirotech.co.uk